Low-Profile, Superabsorbent Laminates.

Since the mid-1980’s, Gelok International has been a premier manufacturer of low-profile, superabsorbent laminates and composites. Gelok laminates can be used directly as an absorbing substrate or incorporated into a wide variety of finished products used to absorb fluids such as water, blood, exudate, urine and other aqueous based solutions, while reducing the bad odors associated with these fluids and bacterial activity.

Applications for low-profile, superabsorbent Gelok laminates include food tray pads, incontinence, medical packaging, medical cleanup, underpads, wound care, urinal pads, filtration and other usages where absorption of water-based fluids is needed. All of Gelok International’s cellulose-based laminates are adhesive-free as they are Hydrogen-bonded to bind the laminate together. By specific request, Non-woven superabsorbent laminates can also be manufactured by incorporating specialized adhesive systems.

Gelok Delivers Super Absorbing Performance.

Using a variety of superabsorbent polymers, Gelok low-profile superabsorbent laminates can absorb many times their own weight of water, exudate or aqueous solution and lock it into a gel to prevent leakage and facilitating easy disposal. Gelok laminate products feature an extraordinarily thin profile and a lightweight composition that result in a lighter and more slender product. They are designed to offer absorbency rates and capacities tailored to meet specific applications. FDA approved grades are available for indirect food contact purposes where the Gelok laminate is the absorbent core.

Gelok Custom Composites

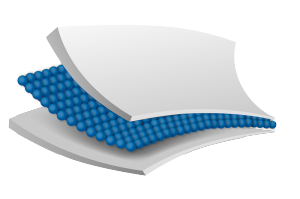

Absorbent Gelok laminates provide tremendous product flexibility due to our custom manufacturing processes. Our laminates consist of superabsorbent polymer granules (SAP) bonded between sheets of cellulose or non-woven material. The degree of absorbency is determined by the amount of polymer and cellulose pulp used in the core. Additionally, the performance characteristics can be enhanced by the use of alternative materials with a wide range of basis weights.

More Manageable Finished Product After Use.

Gelok International’s low-profile, superabsorbent laminates are stable, with excellent fluid retention under pressure, which means once the product has achieved the desired level of absorbency it is still relatively dry and easier to dispose of. There are many reasons to choose Gelok International products to satisfy the demanding absorbency applications that arise every day. Here are a few features our customers have come to appreciate:

- Extraordinary thin profile

- Lightweight, hence a less bulky, lighter end product

- Soft conformable airlaid based composites

- Customizable absorbent laminate to meet customer’s unique needs

- Quick absorbing (actual speed of absorbency varies by application and product design)

- Consistency of finished product

- Easy-to-use commercial form

- Quick start-up with low material waste

Gelok laminates consist of superabsorbent polymer granules bonded to cellulose fibers, tissue or non-woven material. The degree of absorbency is determined by the amount and type of polymer used in the product and the substrate performance characteristics can be enhanced by the use of alternative materials with a wide range of basis weights.

‘Lok’ Fluid In

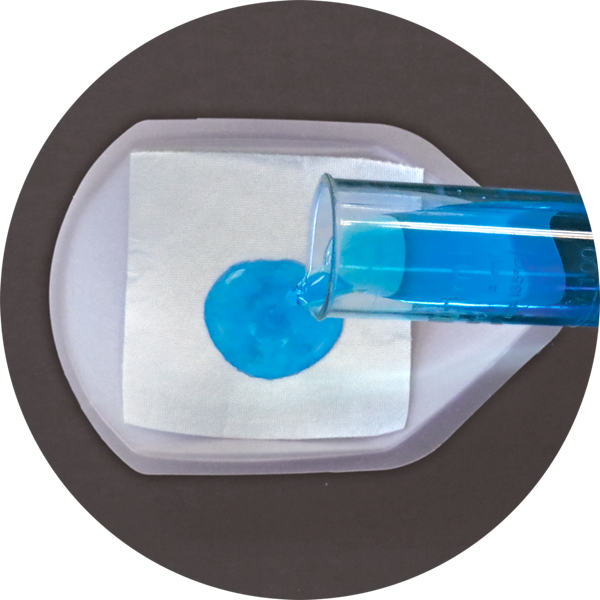

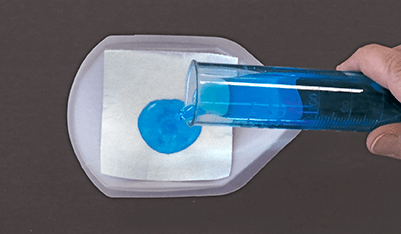

“Lok” fluid in 1: Sample

“Lok” fluid in 2: Liquid

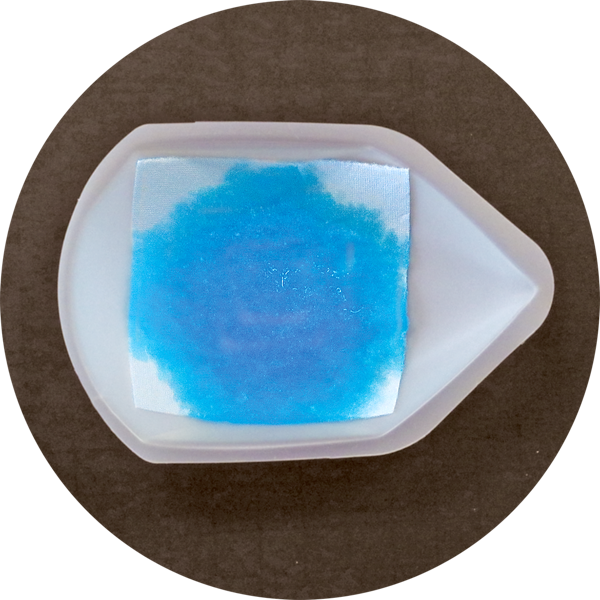

“Lok” fluid in 3: Wicking

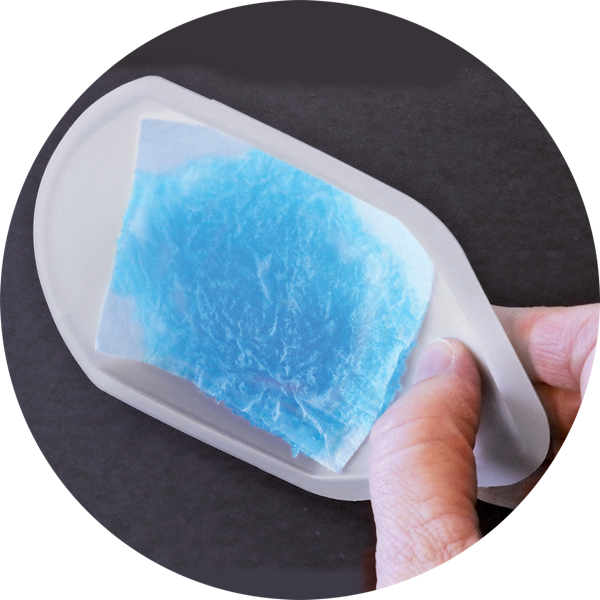

“Lok” fluid in 4: Absorption

Gelok Services

Custom Manufacturing

- Pilot machine testing

- Research and development

- Experienced engineering/chemical staff

Technical Services

- Superabsorbent product design

- Equipment/system design

- Fully equipped laboratory

- Training and education (products and systems)

- Custom services as required

Materials Testing

- Tensile strength

- Absorption rates

- Fluid retention

- Other testing as required

Gelok Laminate Slitting

- Widths from 1-1/2″ (38 mm) to 52″ (1321 mm)

- Untrimmed master roll at 54″ (1370 mm) or 50″ (1270 mm)

- 3″ (75 mm) OD core

- Standard OD 28″ (711 mm)